This work introduces a novel method that enables robots to transport objects with a tray at maximum speed with minimal sliding.

Abstract

Object transport tasks are fundamental in robotic automation, emphasizing the importance of efficient and secure methods for moving objects. Non-prehensile transport can significantly improve transport efficiency, as it enables handling multiple objects simultaneously and accommodating objects unsuitable for parallel-jaw or suction grasps. Existing approaches incorporate constraints based on the Coulomb friction model, which is imprecise during fast motions where inherent mechanical vibrations occur. Imprecise constraints can cause transported objects to slide or even fall off the tray. To address this limitation, we propose a novel method to learn a friction model using acoustic sensing that maps a tray's motion profile to a dynamically conditioned friction coefficient. This learned model enables an optimization-based motion planner to adjust the friction constraint at each control step according to the planned motion at that step. In experiments, we generate time-optimized trajectories for a UR5e robot to transport various objects with constraints using both the standard Coulomb friction model and the learned friction model. Results suggest that the learned friction model reduces object displacement by up to 86.0% compared to the baseline, highlighting the effectiveness of acoustic sensing in learning real-world friction constraints.

Fast Non-prehensile Transport

Advantages of transporting objects with a tray include:

- Handling hard-to-grasp objects easily

- Transporting multiple objects simultaneously

- Avoiding computation for rigid grasps

- Requiring minimal end-effector actuation

However, non-prehensile transport requires carefully balancing forces to avoid damage.

Acoustic-Guided Constraint Learning

Most planners rely on the standard Coulomb friction model to prevent object sliding. However, at high speeds, robot vibrations and subtle dynamics cause objects to move well before the model predicts.

We propose a novel method to learn a friction model using acoustic sensing that maps a tray's motion profile to a dynamically conditioned friction coefficient. This learned model enables an optimization-based motion planner to adjust the friction constraint at each control step according to the planned motion at that step.

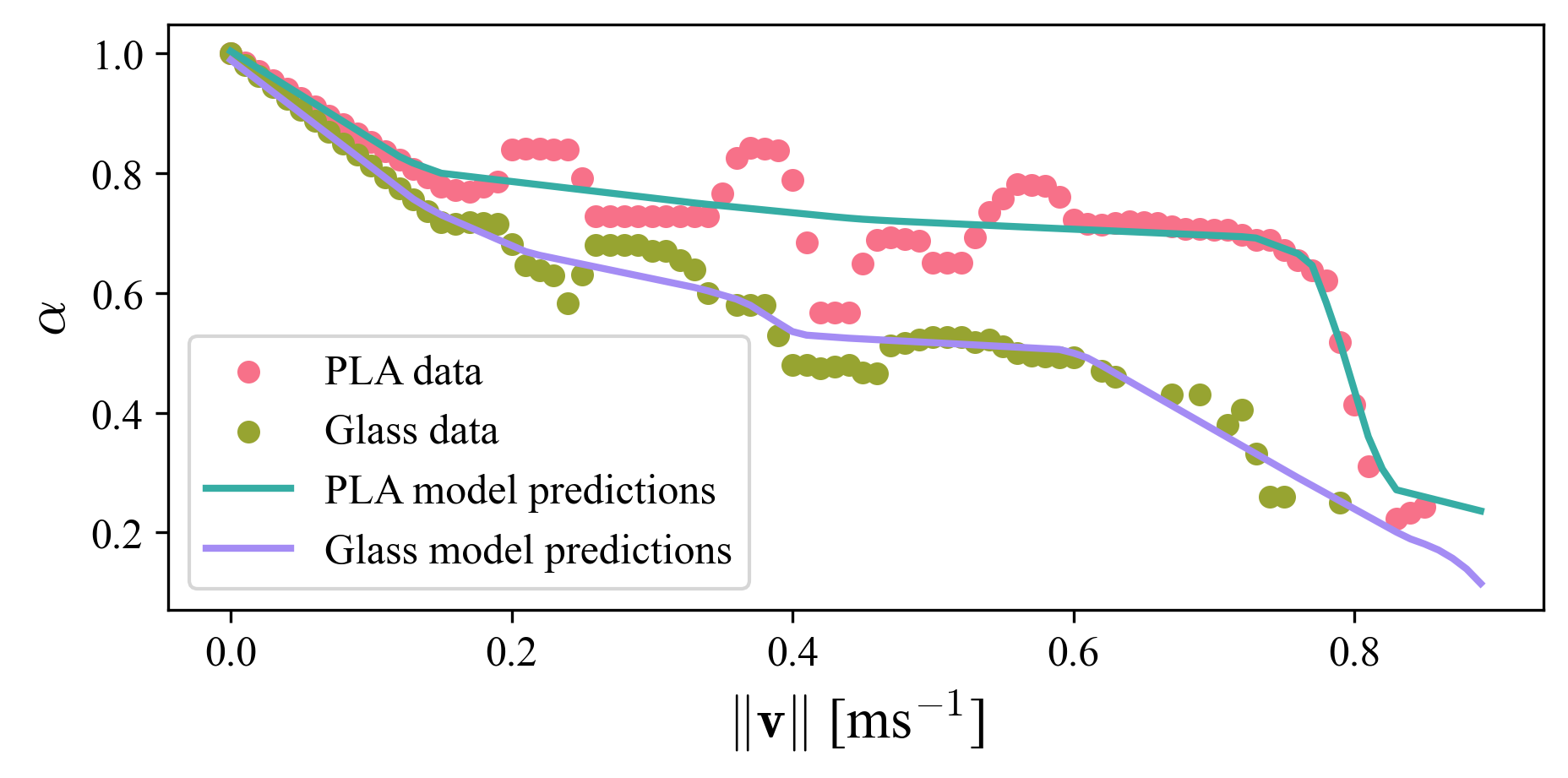

To learn the model, we accelerates the tray with an object on it repeatedly and use a contact microphone to detect when sliding starts, from which we get the accelerations and velocities that trigger sliding. We collect data with a PLA cube and a glass container, and train 2 models.

Experiments

7 Experiments with Single Objects

Cube (1x original speed)

Standard Coulomb Friction Model

Learned Friction Model: PLA

Learned Friction Model: Glass

AS: Coulomb

AS: No Constraints

Gusset (1x original speed)

Standard Coulomb Friction Model

Learned Friction Model: PLA

Learned Friction Model: Glass

AS: Coulomb

AS: No Constraints

Small Glass Container (1x original speed)

Standard Coulomb Friction Model

Learned Friction Model: PLA

Learned Friction Model: Glass

AS: Coulomb

Sample EGAD! Object (1x original speed)

Standard Coulomb Friction Model

Learned Friction Model: PLA

Learned Friction Model: Glass

AS: Coulomb

AS: No Constraints

Coin (1x original speed)

Standard Coulomb Friction Model

Learned Friction Model: PLA

Learned Friction Model: Glass

AS: Coulomb

AS: No Constraints

Big Glass Container (1x original speed)

Standard Coulomb Friction Model

Learned Friction Model: PLA

Learned Friction Model: Glass

AS: Coulomb

Disc (1x original speed)

Standard Coulomb Friction Model

Learned Friction Model: PLA

Learned Friction Model: Glass

AS: Coulomb

AS: No Constraints

3 Experiments with Multiple Objects

3 Gussets (1x original speed)

Standard Coulomb Friction Model

Learned Friction Model: PLA

Learned Friction Model: Glass

AS: Coulomb

AS: No Constraints

4 Coins (1x original speed)

Standard Coulomb Friction Model

Learned Friction Model: PLA

Learned Friction Model: Glass

AS: Coulomb

AS: No Constraints

4 Small Glass Containers (1x original speed)

Standard Coulomb Friction Model

Learned Friction Model: PLA

Learned Friction Model: Glass

AS: Coulomb

2 Experiments with Out-of-Distribution Objects

Sponge: Hard Side (1x original speed)

Standard Coulomb Friction Model

Learned Friction Model: PLA

Learned Friction Model: Glass

AS: Coulomb

AS: No Constraints

Sponge: Soft Side (1x original speed)

Standard Coulomb Friction Model

Learned Friction Model: PLA

Learned Friction Model: Glass

AS: Coulomb

AS: No Constraints

Quantitative Results

Experiments where objects fall off the tray are failure cases. On success, we measure object displacements relative to the tray in millimeters.

| Cube ×1 |

Gusset ×1 |

Glass small ×1 |

EGAD!(a) ×1 |

Coin ×1 |

Glass big ×1 |

Gusset ×3 |

Coin ×4 |

Glass small ×4 |

Disc ×1 |

Sponge(a) hard side |

Sponge(a) soft side |

|

|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

Material μs |

PLA 0.21 |

Aluminum 0.18 |

Glass 0.17 |

PLA 0.21 |

Cupronickel 0.21 |

Glass 0.17 |

Aluminum 0.18 |

Cupronickel 0.21 |

Glass 0.17 |

Polycarbonate 0.30 |

Polymer 0.21 |

Foam 0.25 |

| Coulomb | 18.3 | 15.9 | 15.3 | 18.9 | 14.7 | 8.2 | 16.7 | 18.3 | 13.2 | 15.1 | 21.2 | 13.6 |

| Learned-PLA | 8.1 | 6.1 | 2.8 | 9.8 | 7.6 | 2.6 | 9.0 | 12.4 | 3.1 | 5.3 | 13.7 | 9.9 |

| Learned-Glass | 2.7 | 1.5 | 1.4 | 3.1 | 1.9 | 1.7 | 4.6 | 1.8 | 1.5 | 1.4 | 2.9 | 1.7 |

| AS-Coulomb | 3.9 | 2.7 | 2.1 | 4.4 | 3.2 | 2.3 | 4.6 | 3.6 | 2.3 | 3.8 | 5.8 | 1.1 |

| AS-No Constraints | Fail | Fail | Fail | Fail | 35.2 | -* | Fail | 26.5 | Fail | 21.2 | 38.5 | 15.6 |

|

Assumption violations: (a) uneven contact surface. * Not tested for safety reasons. |

||||||||||||

All objects transported with constraints using the learned friction model show improved performance, with object displacement reduced by an average of 53.9% and 86.0% with the PLA model and the more conservative glass model respectively.